Dubo FAQs

Answer to the FAQs

Would you like to know more about Dubo® or KORREX® products? Check out our FAQs here. If your question isn’t listed, or you need additional information, please don’t hesitate to contact us. We’ll be happy to help you further.

Application

Is the height of a Dubo® toothed collar washer relevant, and does it affect the construction?

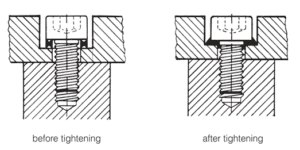

We recommend you use a toothed collar washer with the lowest possible collar height. When tightened, the nut or bolt ‘sinks’ into the Dubo® toothed collar washer. Using the lowest possible washer will give the tool used to tighten the nut or bolt more area to grip the nut or bolt. The height of the washer has no effect on the functionality of the structure. See this drawing for a visual explanation.

How much should a nut or bolt be tightened?

In our customers’ experience, the nut or bolt should be tightened with a spanner to the point that the nylon washer is completely deformed, but still seals properly. How much force this requires can best be determined on the spot based on the result obtained. There are no standard values. The seal between the bolt and the thread is obtained as the washer is deformed.

Is it a good idea to tighten the nut or bolt extra firmly?

A Dubo® retaining washer functions at its best as soon as the outer edge of the washer visibly deforms. At this point, the nylon folds completely around the head of the bolt or nut, and the right amount of pressure is exercised on the retaining washer. Further tightening is not necessary and may even be harmful. Overtightening a Dubo® retaining washer can damage it and prevent it from fulfilling its function.

It looks like the nut or bolt needs to be tightened even more, but is that necessary?

The washer is made of the superpolyamide nylon 6, so the nylon encases the surface around the bolt or nut after tightening. Although it may appear that the bolt or nut should be further tightened, it’s unnecessary. As soon as the retaining washer deforms, it indicates that the tightening is correct. Further tightening or excessive pressure can damage the Dubo® retaining washer, preventing it from fulfilling its function.

How much pressure can be exerted in a bolt when using a Dubo® retaining washer and a toothed collar washer?

A Dubo® toothed collar washer is used in conjunction with a Dubo® retaining washer with high-quality steel bolts (8.8). After the nylon retaining washer has been placed in the toothed collar washer, any desired pressure can be exerted on the bolt without damaging the Dubo® retaining washer.

The Dubo® retaining washer deforms in the toothed collar washer after tightening. Is that a problem?

The Dubo® retaining washer deforms in the toothed collar washer as a direct result of tightening the bolt. This deformation is necessary to obtain the desired locking and sealing; in fact, this principle underlies Dubo products. Under high pressure, the Dubo® retaining washer is perforated by the teeth of the toothed collar washer. This causes deformation in which the toothed collar washer forms a solid unit with the bolt. The bolt is then in direct contact with the steel teeth, creating a partly rigid connection of steel/steel and nylon, and a constant elasticity of the retaining washer.

What is the recommended tightening torque for a nut when using a Dubo® retaining washer without the Dubo® toothed collar washer?

Practice shows that the nut must be tightened with a spanner to the point that the nylon washer is completely deformed but still seals properly. How much force this requires can best be determined on the spot based on the result obtained. There are no standard values. The seal between the bolt and the thread is obtained as the washer is deformed. A Dubo® retaining washer functions at its best as soon as the outer edge of the washer visibly deforms. The nylon then completely encloses itself around the head of the nut or bolt, and the right amount of pressure is exercised on the retaining washer. Further tightening is not necessary and may even be harmful. Additional specifications may be possible, depending on the application. Please let us know if you need more information on this aspect.

Compliance

Is Dubo Dorned the sole supplier of Dubo® washers?

Dubo Dorned is the inventor and sole producer of original Dubo washers and related products. We work with an international network of distributors and dealers, so you can buy original Dubo® products directly from us or through this network. If you buy Dubo® products through us or this network, you know you can rely on the guaranteed quality that we’ve been supplying since 1951.

Do you want to be sure that Dubo® products offered are genuine Dubo® Originals? Ask us, and we’ll be happy to check whether you’re dealing with an authorised reseller or a product from a manufacturer of counterfeits.

What values are guaranteed when using the Dubo® products?

As the exclusive producer of Dubo® Originals, we have acquired extensive knowledge about our product. However, we’re also aware that these products are used in an endless number of applications, so we can never give guarantees. If you want to know something about using our product in a specific application, please get in touch with us. We enjoy sharing our thoughts and give advice where possible.

Are Dubo® and KORREX® products REACH compliant?

Dubo® washers are made of Akulon F223-D. REACH compliance applies to the entire chain, so there’s no specific document available for Dubo® products. The washers are produced by injection moulding. No other substances are added to the base material. If desired, an absence declaration of this base material from our Akulon supplier is available. So as far as we’re aware, no substances listed by the European Chemicals Agency (ECHA) as an SVHC are added during production.

Dubo Dorned can issue a REACH declaration on request. Please let us know if you require any of these documents.

Are Dubo® and KORREX® products RoHS compliant?

Dubo® washers are made of Akulon F223-D. A valid RoHS declaration from the supplier is available. Dubo® retaining washers are produced exclusively with this material and, to our knowledge, no substances are added during production which are listed by the European Chemicals Agency (ECHA) as an SVHC.

KORREX® snap caps and nut caps are produced by injection moulding from HDPE, more specifically Sabic M80064S. A safety data sheet for this material according to EC 1907/2006 is available upon request. Please let us know if you require any of these documents.

Is an SVHC absence declaration available?

Dubo® washers are made of Akulon F223-D. A valid RoHS declaration from the supplier is available. Dubo® retaining washers are produced exclusively with this material and, to our knowledge, no substances are added during production which are listed by the European Chemicals Agency (ECHA) as an SVHC.

KORREX® snap caps and nut caps are produced by injection moulding from HDPE, more specifically Sabic M80064S. A safety data sheet for this material according to EC 1907/2006 is available upon request. Please let us know if you require any of these documents.

Can you issue a 2.1/3.1 certificate in accordance with EN10204/DIN11204?

A mill test certificate (MTC), or mill test report (MTR), is issued by a manufacturer to certify the chemical and mechanical features of a product, and demonstrate it conforms with applicable norms and technical specifications. Mill test certificates normally deal with steel products and adhere to the requirements outlined in the EN10204 standard. A mill test certificate therefore mainly refers to the steel toothed collar washer. Both Dubo® retaining washers and KORREX® insulation bushes are made from nylon, so such certificates are not normally issued for these products, as the composition of the granulate used as raw material is identical in every batch. The traceability of these products is safeguard in our internal QS by the batch code on the packaging.

A declaration of conformity can be issued on request for plastic Dubo® and KORREX® products. Please let us know if you require any of these documents.

Are Dubo® and KORREX® products CE certified?

Any construction product in the European Economic Area (EEA) must comply with the EU Construction Products Regulation (CPR). This law states that all products traded or sold in Europe must bear a CE mark if a harmonised standard exists for the product. A CE mark indicates that a product complies with the regulation. It doesn’t necessarily mean that a product will be suitable for all end uses but does show that the product is consistent with its Declaration of Performance (DoP) issued by the manufacturer. As there is no harmonised standard for Dubo® retaining washers, there is no possibility or requirement to have a CE marking or DoP for these products.

Material properties

How should Dubo® retaining washers and other polyamide products be stored?

It’s essential that Dubo® products are stored correctly. In the right conditions, the shelf life is usually very long. Ideally, Dubo® products should be stored at around room temperature with normal humidity (40% to 60%).

Dubo® retaining washers are made of polyamide. This is a hygroscopic material, which absorbs and releases water in a reversible process. Parts made of this material tend to achieve a state of equilibrium with the humidity around them. For practical purposes, the saturation state after immersion in water and the state of equilibrium in a standard atmosphere (DIN 50014: 23 °C, 50% relative humidity) are generally taken into account.

The mechanical properties of Dubo® retaining washers, especially flexibility and minimum tensile strength, are significantly affected by the water content. In a standard atmosphere of 23 °C and 50% relative humidity, the degree of water saturation of polyamide is around 2.5%. To apply Dubo® retaining washers in the best conditions, it’s therefore important that the polyamide has a water content of approximately 2.5% in a state of equilibrium.

Deliberately modifying the properties of plastics through the controlled absorption of water is called conditioning. Conditioning is used to rapidly reach the state of equilibrium that can be expected in a part during subsequent use. Moulded parts in polyamide only achieve their elastic properties and definitive dimensions after conditioning. During production, our washers are conditioned by immersion in water.

If washers are stored in relatively dry conditions, subject to large temperature fluctuations or exposed to high levels of UV, they will lose moisture. Dry washers may become very brittle. This effect can easily be reversed by immersing them in water again for some time (48 hours), until they are fully saturated.

Since the quality and functionality of our products are affected by their water content, we recommend Dubo products are stored in appropriate conditions as described above.

What load can Dubo® washers withstand when they’re used to protect against galvanic corrosion?

Dubo® washers and insulation bushes are used in an extremely wide range of applications, so we’re unable to give any guarantees or issue guidelines with regard to the possible maximum load.

Do Dubo® retaining washers have a protection class against moisture penetration?

IP codes apply to electrical enclosures rather than to the parts themselves. Since the washers generally deform during application, the resistance to dust and water intrusion depends on the characteristics of the application. Washers should therefore be tested in the actual application to determine whether the construction complies with IEC 60529. We have no information on hand for the washer itself.

Which tolerances and possible variations in size apply to Dubo® and KORREX® products?

Dubo® retaining washers are manufactured by injection moulding of nylon base material. As the moulds have multiple positions, in theory there could be some variation in the size of washers. However, the moulds are fixed in size, and any variation is within specification. More importantly, these washers are designed to be deformed anyway when applied correctly, so their shapes change completely after tightening with the appropriate torque (see image below). This is necessary for the full retaining effect. The washer spreads around the bolt head and into the thread. The functionality of the washer is not compromised in any way by a slight variation in size.

Can a Dubo® retaining washer break when the bolt or nut is tightened? Polyamide is flexible, isn’t it?

In general, the washers shouldn’t crack at all. They are designed to resist a torque that completely deforms the washer. If a washer does crack, it’s usually because it wasn’t stored properly. During our production process, moulded washers are conditioned in water. One of nylon’s characteristics is that it absorbs and maintains a certain amount of moisture to remain flexible. If washers are stored in low humidity or heat, or exposed to certain amounts of daylight or UV, this moisture evaporates, and the washers can become very brittle. This effect can usually be reversed by immersing the washer in water again for around 48 hours. The shelf life is normally very long if the storage requirements are respected; ideally at around room temperature, with normal humidity (50% to 60%).